Stewart Filmscreen StudioTek 130 G4 Projection Screen Review Stewart Factory Visit

After completing my StudioTek 130 G4 review, I found myself on a calibration tour in Southern California and took the opportunity to reach out to Stewart Filmscreen and arrange a visit to its headquarters and manufacturing facility in Torrance. I had never visited Stewart before, and Mark Robinson, Vice President of Customer Experience and the scientist behind the company's screen materials, was gracious enough to spend a half-day taking me through the facilities and providing a look at the company's manufacturing process.

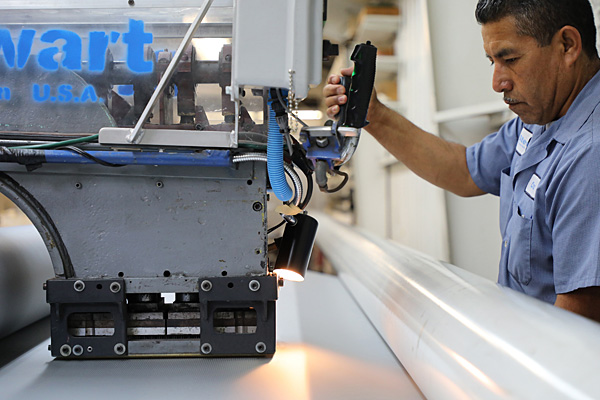

During the two decades I've been in this industry, I've heard a lot of enthusiasts mention the premium prices Stewart charges for its screens and make value comparisons to other brands. While I agree that Stewart charges a premium, I've also always felt that the company's products set a high benchmark for construction and craftsmanship. That became readily apparent during my tour, where I witnessed pride in manufacturing and meticulous attention to detail. Stewart makes the majority of its screen materials on location, and it was very impressive to witness that process.

A highlight of my visit was seeing rooms where the screen material used for everything from massive commercial cinema screens to home theater-size versions were made completely from scratch without a seam in sight. I also toured fabrication facilities teeming with workers doing most of the frame-cutting and assembly by hand and witnessed a meticulous QC process that involved going over every inch of material to detect even the slightest imperfections. Robinson went over each process and pointed out the attention that went into every product, from the hand-wrapping of frames with light-absorbing black velvet material to the perforation of home and cinema screens to make them acoustically transparent.

Stewart is ISO 9001:2015 certified and Robinson emphasized the company's "Continuous Improvement" philosophy, which dictates that screen materials and coatings get regularly upgraded, with the "Generation" level changed only when they feel the product offers an appreciable step-up in performance from the previous version. (Improvements Stewart has made in the product coatings for the ST130 G4 material I reviewed are already being evaluated for other screens the company makes, including the UltraMatte 150 and GrayHawk.)

During my visit, I got a sneak peek at a new weave material offering better acoustic transparency that Stewart plans on bringing to the market soon, a new material for ultra-short throw projection applications, and early prototypes of a new high ambient light rejecting (HALR) screen. I also saw new motorized screen options in the company's R&D facilities, including a screen that rises from the floor for ultra-short throw projection systems and an updated VistaScope for widescreen installations. Needless to say, Stewart is continuously innovating and trying to deliver the best solution for any screen application.

Stewart also plays a big part in commercial installations outside of the home theater market. While that includes screening rooms, theaters, and schools, they also make screens for museums, simulation, and even VR. I saw pretty incredible custom screen-building solutions and reflective surfaces for specialized applications during my visit, but since all of those are designed in-house, I was not permitted to take photographs.

My visit to the Stewart Filmscreen factory was a great opportunity to witness first-hand the focus and dedication the company puts into its products. With manufacturing handled in-house, they achieve a staggering level of quality as every variable is controlled from start to finish. That's a rare thing nowadays when many companies design products, but then farm the final work out elsewhere with the hope that the end result meets expectations.—KRD

Note: The Where to Buy link below is an affiliate link. If you purchase through the link, we may earn a small commission at no extra cost to you. Thank you for your support!

- Log in or register to post comments