Transparent Ambition is my favorite field. I often discuss this problem with my friends from time shooter 2 and it always is my favorite issues.

Transparent Ambition

When you see a movie in a commercial cinema, it's easy to suspend disbelief and pretend you're watching the action through a window. One important reason for this is the fact that the sound of the characters' voices seems to come from their apparent location, rather than from above or below the screen.

Scott inspects the Screen Research CP2 screen with a light source behind it. Without a light source, the screen is visually opaque, but it remains acoustically transparent.

Cinemas accomplish this effect by using an acoustically transparent screen, which is perforated with millions of tiny holes that allow sound from the speakers behind the screen to pass through with minimal distortion. In the case of Stewart Filmscreen's commercial products, the holes are 0.04 inches in diameter, and there are 5,500 of them per square foot. In total, these holes occupy about 8.5 percent of the screen's surface area, and they're invisible from a normal seating distance.

Fig. 1: Stewart microperf screens have 30,000 holes per square foot, and they are oriented in a diamond pattern to minimize moiré distortion.

The same technology is available for home theaters from Stewart and other screen makers. In Stewart's home-oriented products, the holes are 0.02 inches in diameter, and there are 30,000 per square foot (see Fig. 1), which accounts for about 10 percent of the total surface area. Because these holes are smaller and closer together than those in commercial screens, Stewart's acoustically transparent products are known as microperf screens.

Fig. 2: Screen Research woven screens let sound through the gaps between fibers, which naturally form a diagonal pattern to reduce moiré.

A new company called Screen Research is taking a different approach. Instead of perforating a solid sheet with tiny holes, they use a specially woven fabric with small, naturally occurring gaps between the proprietary, patented microfibers (see Fig. 2). The gaps in the company's ClearPix1 (CP1) material occupy about 1 percent of the total surface area, while the gaps in the ClearPix2 (CP2) material cover less than 3 percent of its total surface area. Unlike microperf screens, which transmit sound solely through the holes, sound waves are transmitted primarily around the microfibers throughout the woven material.

In an ongoing effort to quantify home theater standards, THX tests and certifies acoustically transparent screens for their sonic and visual performance. Among the screens that have received THX certification are three of Stewart's microperf models and Screen Research's two woven products.

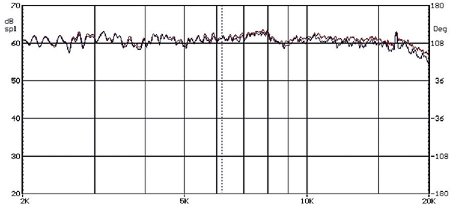

Fig. 3: Using an outboard equalizer, Stewart microperf screens exhibit a relatively flat frequency response. This measurement was taken with the speaker 12 inches behind the screen.

Sound

All acoustically transparent screens affect sound in one way or another, so the moniker is somewhat misleading. However, manufacturers go to great lengths to minimize the effect. According to THX, woven screens generally have less effect on sound than microperf screens, at least in the models they've certified. Microperf material can be made to behave properly, but it takes more effort.

Fig. 4: This frequency-response measurement was taken with the speaker 4 inches behind a Screen Research woven screen. No equalization was used.

All acoustically transparent screens attenuate the overall level and exhibit a high-frequency rolloff, for which you can compensate with equalization, if necessary. In fact, commercial-cinema sound systems equalize the front channels for just this purpose. To perform the same task at home, Stewart microperf screens come with an outboard equalizer (see Fig. 3). According to Stewart, without equalization, their microperf screens start to roll off at around 5 or 6 kilohertz and drop by about 2 decibels per octave. Screen Research says their woven screens' rolloff starts at 10 kHz and drops by 1dB/octave, which means they need no equalization (see Fig. 4).

Another critical sonic effect is controlled by the speaker's distance from the back of the screen. If you place the speaker too close, much of the acoustic energy will get trapped between the speaker and screen, causing a comb-filtering effect that is impossible to equalize. If you place the speaker too far away, the screen's frame becomes an issue, interfering with the sound waves. To avoid these problems, THX recommends that you place the speaker 6 to 12 inches behind the screen. According to THX, comb-filtering is much less of an issue with woven screens, which means you should be able to put the speaker closer to the screen; however, Screen Research claims that you can place speakers within an inch of their screens with no comb-filtering.

To further improve the sound of a speaker behind a microperf or woven screen, THX recommends that you put damping material on the speaker's front baffle, as well as on the wall behind the speaker. A dark fuzz that's a couple of inches thick is ideal to reduce reflections behind the screen. Why must the fuzz be dark? It has to do with the visual characteristics of acoustically transparent screens, which is my next point of discussion.

Picture

Aside from allowing sound to pass through them, microperf and woven screens must also preserve the quality of the image being projected onto them. In this regard, one advantage of all acoustically transparent screens is that they can provide the perception of better blacks because of the holes. However, there is a caveat: The area behind the screen must be dark. If this area is light in color, it can wash out the image.

Fig. 5: If the pattern of lines between pixels matches up with the pattern of holes in a microperf screen, moiré distortion like this can occur.

To address this issue, Screen Research offers an optional black woven backing that greatly reduces light leakage from behind the screen, while remaining acoustically transparent. (Like the screen material, it's THX-certified.) According to the company, this backing improves the screen's black-level performance without affecting whites or colors. In addition, they say the backing material obviates the need for fuzz on the speaker or wall, because the backing—along with the screen material itself—absorbs much of the sound energy that doesn't make it through, greatly reducing reflections from the back of the screen.

Digital projectors can cause another potentially image-destroying problem when used with acoustically transparent screens, particularly microperf models. These projectors form their image as an array of pixels, which are separated by thin black lines. When this pattern of black lines overlays the pattern of holes in the screen, a type of visible distortion called moiré can rear its ugly head. Under the right conditions, moiré manifests itself as an interference pattern of straight or curved lines (see Fig. 5).

One such factor is the display technology itself—specifically, the width of the lines that separate the pixels. As this width decreases, so does the chance of moiré. In LCD projectors, the pixels occupy about 70 percent of the image, with 30 percent taken up by the black lines; this is why LCDs suffer the most from the dreaded screen-door effect. DLP pixels occupy 88 percent of the image (Texas Instruments claims 100 percent with their SmoothPicture technology), while LCOS pixels occupy more than 90 percent of the image.

Also important is the precise implementation of a given technology by a manufacturer. For example, Stewart found that they could not get the Panasonic PT-AE700U 1280x720 LCD projector to produce moiré on a microperf screen, while the Sony VPL-HS51 Cineza, another 1280x720 LCD model, exhibited lots of moiré.

You can reduce moiré by orienting the screen's hole pattern at a diagonal angle to the projector's screen-door pattern so the two patterns do not overlap precisely. For this reason, Stewart orients their microperf holes in a diamond pattern (see Fig. 1).

As I mentioned earlier, Screen Research woven screens do not rely on holes per se—the sound travels around the microfibers, and the gaps between them occupy only 1 to 3 percent of the total surface area—so there is little chance of moiré in any event. The company claims that their CP1 material completely avoids moiré at any screen size with any digital-projection technology, while the CP2 material should be at least 70 inches wide to preclude moiré.

Acoustically Invisible

Whether you opt for a microperf or a woven one, an acoustically transparent screen has another advantage over a solid screen: It does not reflect sound in the room, whereas a solid screen does. This can cause uneven sound, creating acoustic hot spots in certain seating locations. Acoustically transparent screens avoid this problem altogether. So if you want the best re-creation of a commercial cinema at home, look into an acoustically transparent screen; if you set it up properly, you're bound to like what you see—and hear.

Stewart Filmscreen

(800) 762-4999

www.stewartfilm.com

Screen Research

Dist. by StJohn Group

(805) 647-3779

www.screenresearch.com

- Log in or register to post comments